Coro-Flo® LPG Turbine Pumps

Corken’s Coro-Flo® regenerative turbine pump has a strong reputation for being a long lasting pump. The free-floating impeller minimizes wear and delivers years of trouble-free service. The Coro-Flo turbine pump is continuous duty and an excellent choice for low flows and moderate to high differential pressures. The liquid is circulated between the teeth of an impeller as it rotates between the pump casing and head. Since the impeller is free floating, there’s no metal-to-metal contact so the pump is virtually maintenance free. Corken offer several models of regenerative turbine pumps with a wide range of differential pressures and capacities.

Suitable for LPG (propane & butane), agricultural ammonia, and numerous other liquefied gases. (C-models are for LPG use only)

C-Model Turbine Pumps

The close-coupled design of a C-model turbine pump makes installation easy and eliminates alignment issues. Ideal for dispensing applications like propane cylinder filling stations and dispensers. Five models available with NPT connections only.

- Close-coupled design is ideal for tight spaces and dispensing cabinets

- Mounts directly to a Corken supplied C-Face motor

- No coupling is required so installation is quick and easy

- Ideal for dispensing applications

- Available in five pump sizes

- Single-stage pump

- Close-coupled design is compatible with a 1, 2, or 3 hp motor

- Motor or wall mounted starters available

- Mechanically seal with silicon carbide seal seat

- Available with NPT connections only

- Approved by Underwriters’ Laboratories (UL) for LPG and agricultural ammonia service only

| Flow Rate | up to 40 gpm (151.4 l/min) |

| Working pressure: | up to 400 psi (27.6 bar) |

| Differential pressure: | up to 150 psi (10.3 bar) |

| Temperature range: | -25 to 225°F (-32 to 107°C) |

| Viscosity: | up to 400 SSU (88 cSt) |

- Pump casing and heads: Ductile ironImpeller: Bronze only

- Shaft: Steel only

- Seal seat: Silicon carbide

- Seal sleeve and follower: Aluminum only

- Seal rotor: Carbon only

- Seal metal parts: Steel only

- Seal housing: Cadmium plated steel only

- O-rings: Buna-N only

- Ideal for low capacity applications with medium head requirements

- Free-floating eliminates metal-to-metal contact and minimizes wear between the pump casing, impeller, and cover

- The balanced mechanical seal and sleeve enhance the sealing performance

- No vibration or pulsation – delivers years of quiet trouble-free service

- Compact, close coupled design eliminates alignment issues and makes installation easy

- Does not require a coupling and coupling guard so installation costs are minimizedFull access to internals by simply removing the pump cover

- Motors have a automatic condensate drain

- Pump nozzles can be rotated in 90 degree increments

- Bypass and pressure gauge connections are provided on the outlet nozzle

- Continuous-duty service

- Butane

- Propane

- Propane cylinder filling

- Liquefied gas transfer

- Dispenser cabinet

- Alternative fuels

- Liquefied gases

- Alternative fuels

- Liquefied gases

- Truck & transport

- Liquid terminals

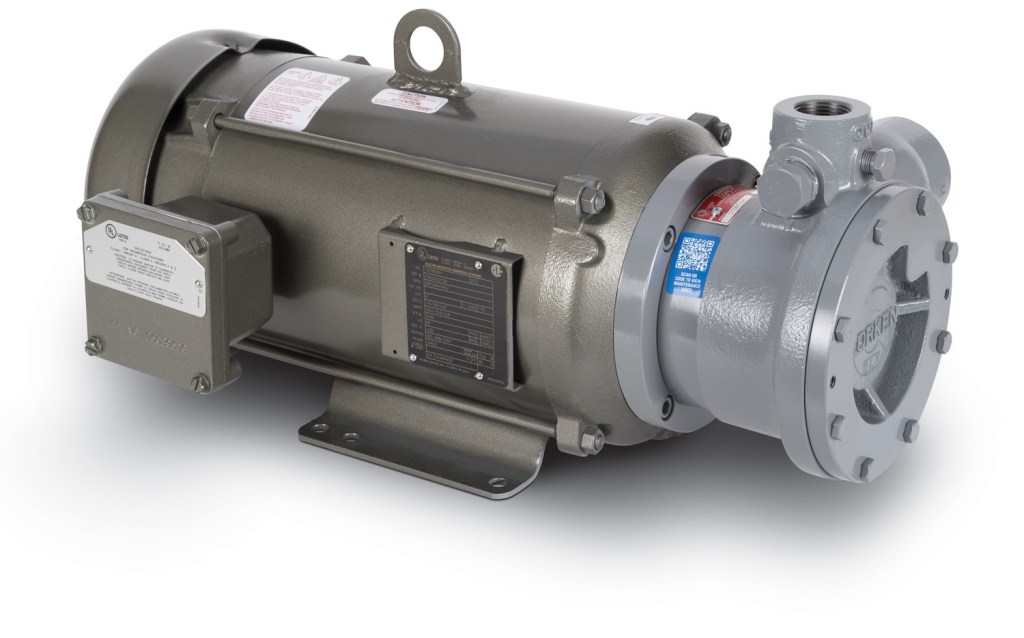

DL, DLD & DLF-Model Turbine Pumps

The DL, DLD, and DLF-model regenerative turbine pump is a direct mount made for a standard, two pole C-Face motor with a 8.5″ rabbit diameter. A 8.5″ rabbit diameter fits 182TC, 184TC, 213TC and 215TC motor frames. The advantage of a direct mount is no coupling guard, baseplate, or special alignment procedures are required for installation. Connections include NPT, Class 300 RF, and DIN.

- Direct mount fits a standard, two pole C-Face motor with an 8.5″ rabbit diameter

- Fits 182TC, 184TC, 213TC and 215TC motor frames

- Frame supports both the pump and motor so they can be directly coupled

- Eliminates the coupling guard, baseplate, and alignment issues

- Available in nine pump models

- Single-stage pump

- A direct mount design utilizes a special bracket that accepts a standard two-pole motor with a 8.5″ rabbit diameter

- The pump and motor are coupled directly to the mount

- Direct mount accepts 3 to 10 hp motors

- Fits 182TC, 184TC, 213TC, and 215TC motor frames

- Mechanical seal with silicon carbide seal seat

- NPT, Class 300, and DIN

- Approved by Underwriters’ Laboratories (UL) for LPG and agricultural ammonia service

| Flow Rate | up to 50 gpm (189 l/min) |

| Working pressure: | up to 400 psi (27.6 bar) |

| Differential pressure: | up to 250 psi (17.2 bar) |

| Temperature range: | -25 to 225°F (-32 to 107°C) |

| Viscosity: | up to 400 SSU (88 cSt) |

- Pump case and cover: Ductile iron

- Impeller: Bronze, ductile iron, steel or stainless steel

- Shaft: Steel or stainless steel

- Seal seat: Silicon carbide

- Seal sleeve and follower: Aluminum or stainless steel

- Seal rotor: Carbon only

- Seal metal parts: Steel only

- Seal housing: Cadmium plated steel, or stainless steel

- O-rings: Buna-N and Neoprene® (Registered trademarks of DuPont)

- Ideal for low capacity applications that require medium to high head

- Free-floating impeller with no metal-to-metal contact minimizes wear between the pump casing, impeller and cover

- The balanced mechanical seal and sleeve enhance the sealing performance

- No vibration or pulsation – delivers years of quiet trouble-free service

- Full access to internals by simply removing the pump cover

- Pump nozzles rotates in 90 degree increments

- Bypass and pressure gauge connections on the outlet nozzle

- Continuous-duty service

- Agricultural ammonia

- Butane

- Propane

- Many more liqueifed gases

Liquified gas trasfer

- Alternative fuels

- Liquefied gases

F, FD & FF-Model Turbine Pumps

The F, FD, and FF-Model frame mount design requires a baseplate, coupling, and coupling guard and utilizes a direct drive configuration so the pump runs at motor speed. With a frame mount design, the user has the flexibility to choose from a variety of motor sizes. FF- & FD-models 060, 075, and 150 produce higher differential pressures than F-Model pumps and are commonly used in autogas applications.

- Frame mount design with a direct drive configuration and mounts to a baseplate

- Utilizes a coupling and coupling guard

- Accepts a variety of motor types

- Available in twelve pump models

- Single-stage pump

- Frame mounted design

- Accepts wide range of motors (1 to 15 hp)

- Direct drive (baseplate, flexible coupling, and coupling guard)

- V-belt drive (baseplate, adjustable driver slide base, V-belt drive, and belt guard)

- Mechanically seal with silicon carbide seal seat

- Available with NPT, Class 300 RF, DIN connections

- Approved by Underwriters’ Laboratories (UL) for LPG and agricultural ammonia service

| Flow Rate | up to 50 gpm (189 l/min) |

| Working pressure: | up to 400 psi (27.6 bar) |

| Differential pressure: | up to 250 psi (17.2 bar) |

| Temperature range: | -25 to 225°F (-32 to 107°C) |

| Viscosity: | up to 400 SSU (88 cSt) |

- Pump case and cover: Ductile iron

- Impeller: Bronze, ductile iron, steel or stainless steel

- Shaft: Steel or stainless steel

- Seal seat: Silicon carbide

- Seal sleeve and follower: Aluminum or stainless steel

- Seal rotor: Carbon only

- Seal metal parts: Steel only

- Seal housing: Cadmium plated steel, or stainless steel

- O-rings: Buna-N and Neoprene® (Registered trademarks of DuPont)

- Ideal for low capacity applications that require medium to high head

- Free-floating impeller with no metal-to-metal contact minimizes wear between the pump casing, impeller and cover

- The balanced mechanical seal and sleeve enhance the sealing performance

- No vibration or pulsation – delivers years of quiet trouble-free service

- Full access to internals by simply removing the pump cover

- A frame mount includes two sets of heavy duty ball bearings long term performance

- Pump nozzles rotates in 90 degree increments

- Bypass and pressure gauge connections on the outlet nozzle

- Continuous-duty service

- Agricultural ammonia

- Butane

- Propane

- Many more liquified gases

- Cylinder filling

- Aerosol propellant/filling

- Liquefied gas transfer

- Vaporizer feed

- Alternative fuels

- Liquefied gases