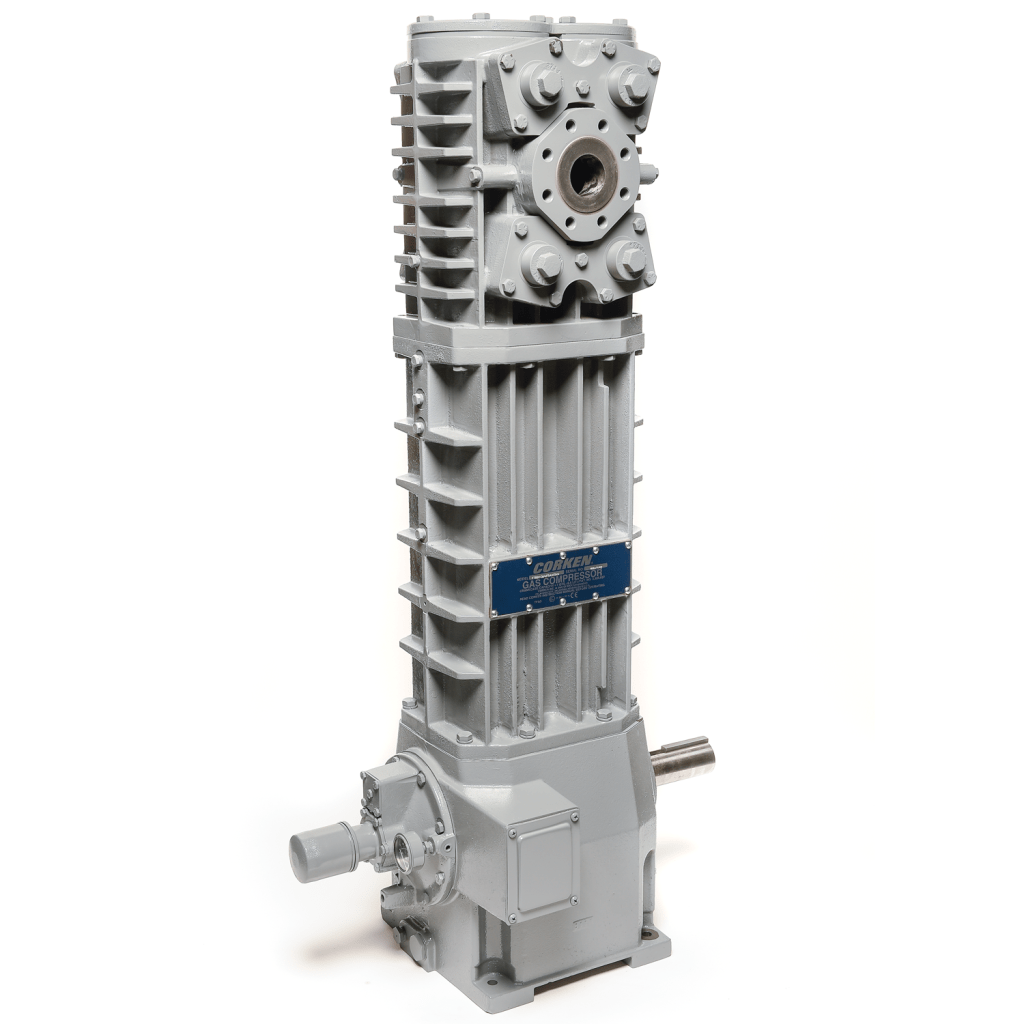

LPG Vertical Compressors

| Many LPG (propane & butane) and agricultural ammonia piping systems do not have ideal conditions for net positive suction head (NPSH). As a result the poor NPSH conditions lead to excessive pump maintenance. Since reciprocating compressors are only exposed to vapors, poor NPSH conditions are not a factor. Many LPG and agricultural ammonia pressurized tanks such as tank cars and buried tanks have top unloading connections. A reciprocating compressor is the perfect solution for transferring liquids in this type of application.

Most Corken vertical LPG reciprocating compressors have single packed piston rods and none offer oil-free gas compression. The only exception is the model D891 which has two sets of packing (one V-ring and one segmented) but it is not oil free. Single packed, non oil-free compressors are typically used in non-corrosive and non-toxic applications where oil-free service and leakage containment are not critical. Typical applications include propane, butane, agricultural ammonia, and natural gas. |

LPG Reciprocating Compressors (Non Oil-Free)

Single packed compressors are typically used in non-toxic, non-corrosive applications where oil-free gas and leakage containment are not critical. LPG (propane & butane), agricultural ammonia, and natural gas applications are where a single packed compressor fits well.

- Utilizes one set of V-ring packing per piston rod

- No distance piece between the cylinder and crosshead guide

- Not oil free

- Single stage compression

- Ideal for non-toxic, non-corrosive applications where oil-free gas and leakage containment are not critical

- One packing set per piston rod

- Does not offer oil-free compression

- Utilizes a V-ring packing design (V-rings, a male and female packing ring, washers, and a spring)

- Single stage design only (exception: model 891 offer two-stage compression)

- Four single-acting models (91, 291, 491 & 691) and one double-acting (D891)

- Cylinder sizes are 3.0″, 4.0″, and 4.5″Available with NPT or Class 300 RF connections

| Piston Displacement | up to 117 cfm (198.8 m3/hr) |

| Working Pressure: | up to 450 psi (31 bar g) |

| Brake Horsepower | up to 45 hp (34 kw) |

| Maximum Outlet Temperature | 350°F (177°C) |

- Head and cylinder: Ductile iron

- Crosshead guide, crankcase, flywheel and bearing carrier: Gray iron

- Valve seat and bumper: stainless steel or ductile iron

- Valve plate: PEEK or stainless steel

- Valve spring: Stainless steel

- Pistons: Ductile iron, gray iron, stainless steel

- Piston rings: PTFE (glass and moly filled)V-ring packing: PTFE (glass and moly filled)Packing cartridge: Ductile iron

- Crankshaft: Ductile iron

- Connecting rod: Ductile iron

- Connecting rod bearing: Bimetal Babbitt

- Wrist pin: Steel

- Wrist pin bushing: Bronze

- Main bearing: Tapered roller

- O-rings: Buna-N, Neoprene® (Registered trademark of the DuPont)

- All cylinders and heads are made of ductile iron for maximum thermal shock endurance

- A single packed compressor is a great low cost option for applications where oil-free gas and leakage containment are not critical

- Valve design offers quiet operation, high efficiency and greater durability

- The step-cut design of the self-lubricating piston rings provides higher efficiencies during the life of the piston ring

- Positively locked pistons allows end clearance to be precisely set to provide maximum efficiency and long life

- Packing sets are a spring loaded seal design that self adjusts to compensate for normal wear

- Adjustable packing screw ensures maximum sealing capacity throughout the life of the packing (exception: model 891)Cast iron crossheads provide superior resistance to corrosion and galling

- Pressure-lubricated crankcase with filter keeps the internals well lubricated at all times and minimizes premature wear

- Agricultural ammonia

- Butane

- Natural gas

- Propane

- And many more

- Vapor recovery

- Liquefied gas transfer

- Pressure boosting

- Tank evacuation

- Rail car loading and unloading

- And many more

- Oil and natural gas production

- Liquefied gases

- Truck and transport

- Liquid terminals

- Marine